Conversion Cost per Unit Produced

Utilization Growth %

ROI / Value Creation per Unit Time per Unit Area

Cost of Maintenance per Unit Produced

Safety & Risk Management

ROI / Production Agility

Digital Tool Scatter / Integration Complexity

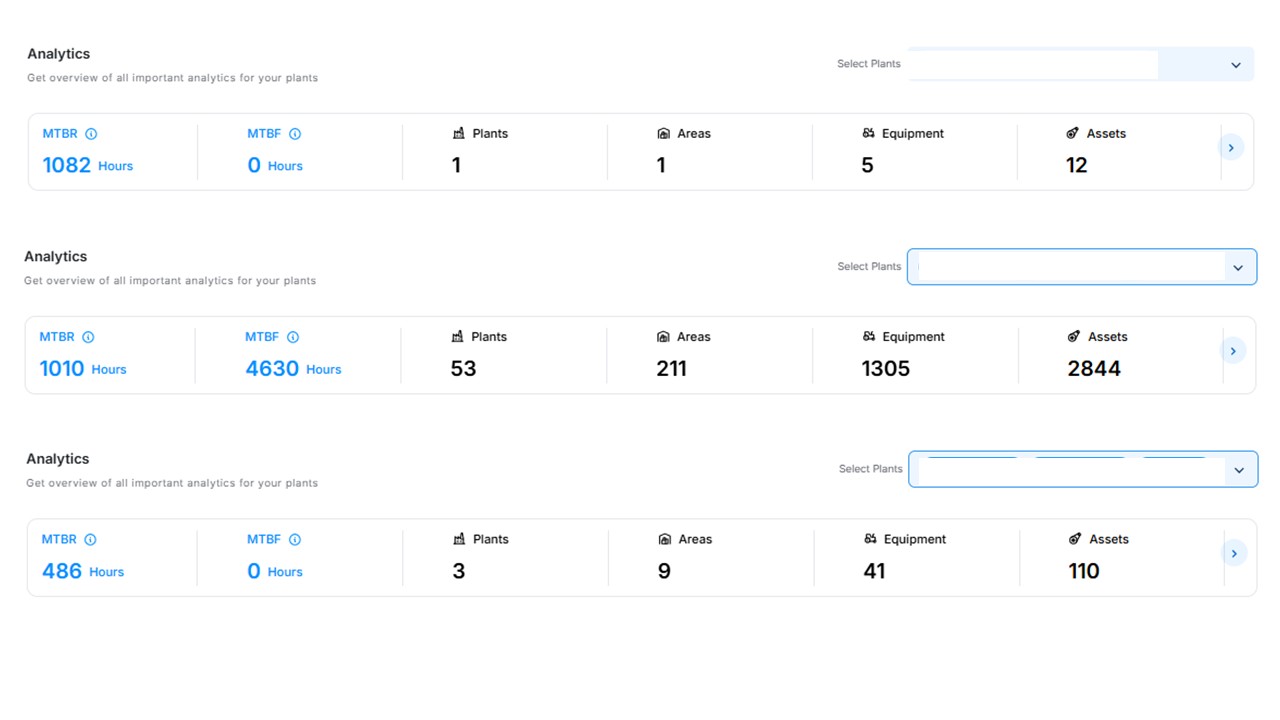

AI-driven Site-wise Dashboards + Schedules

ROI-centric Digital Transformation

Output Growth %

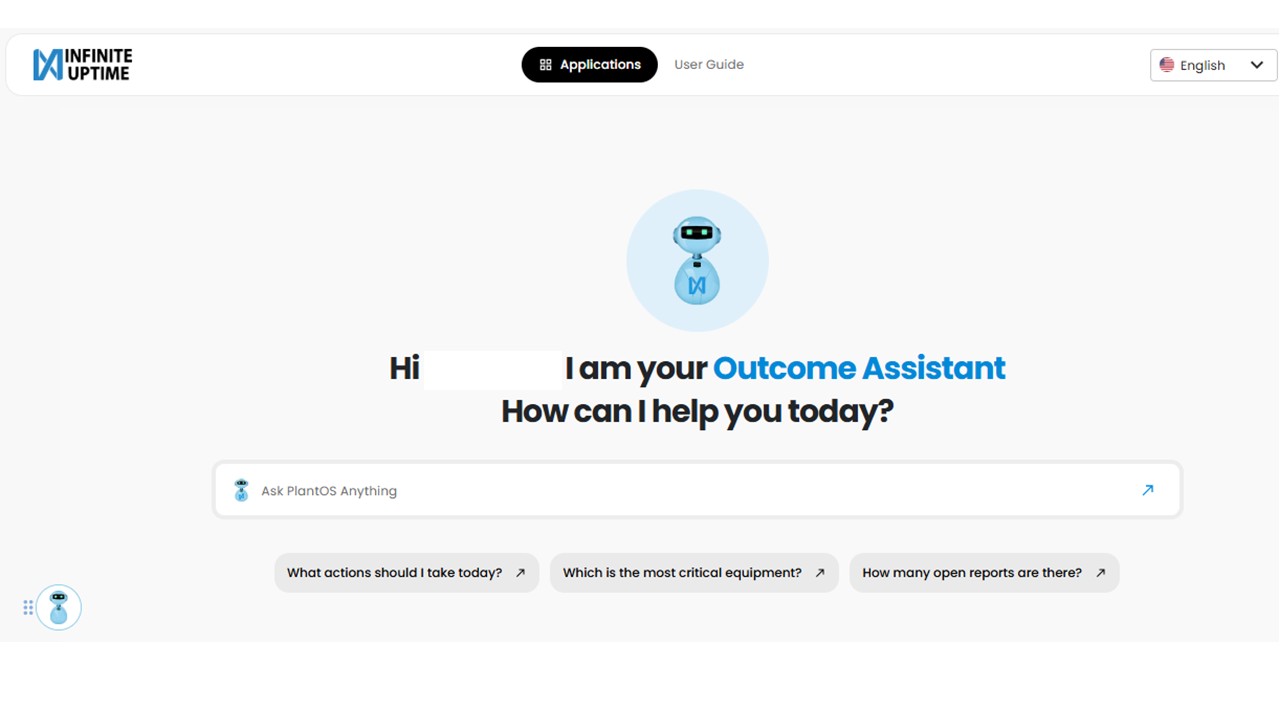

% Decisions Based on AI Prescriptions

Cost Competitiveness

Unscheduled Downtime

% AI Prescriptions Accepted & Acted Upon

Asset Reliability

Cost of Energy per Unit Produced

Energy Efficiency

Productivity Growth %

Digital Ways of Working

Digital Transformation ROI

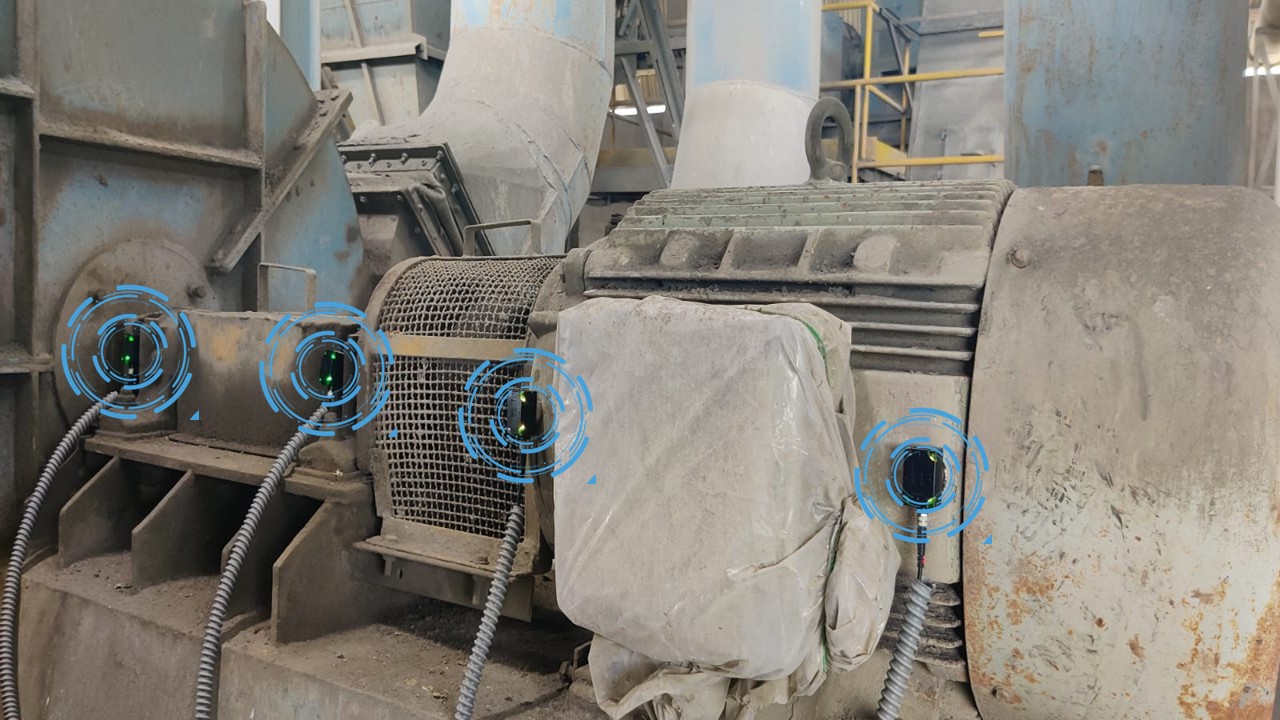

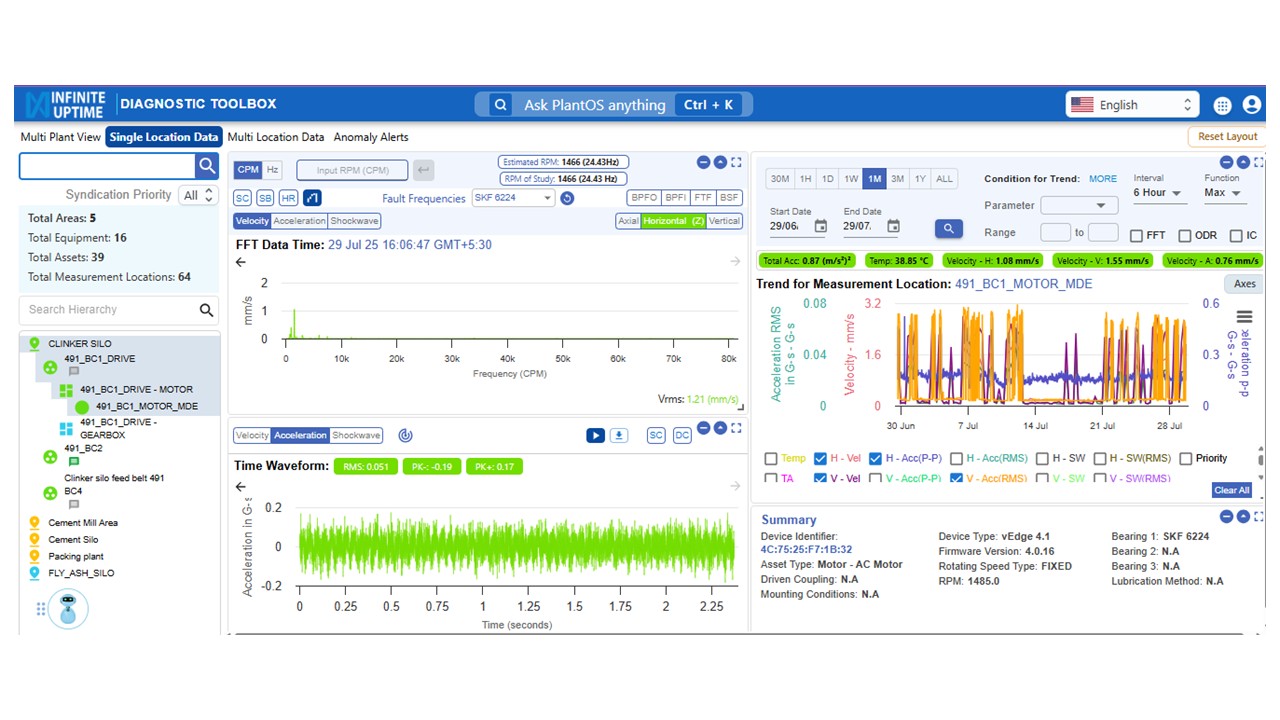

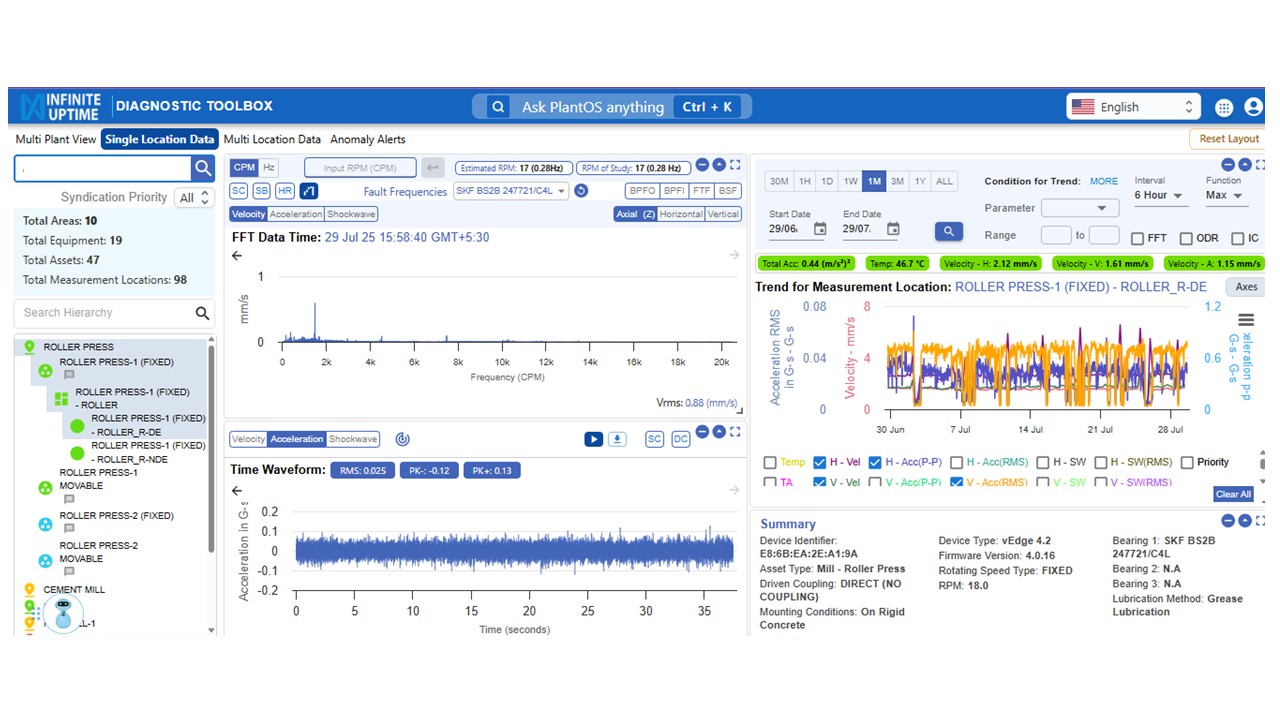

Critical Equipment

Gearbox, main drive and separator gearbox are key components.

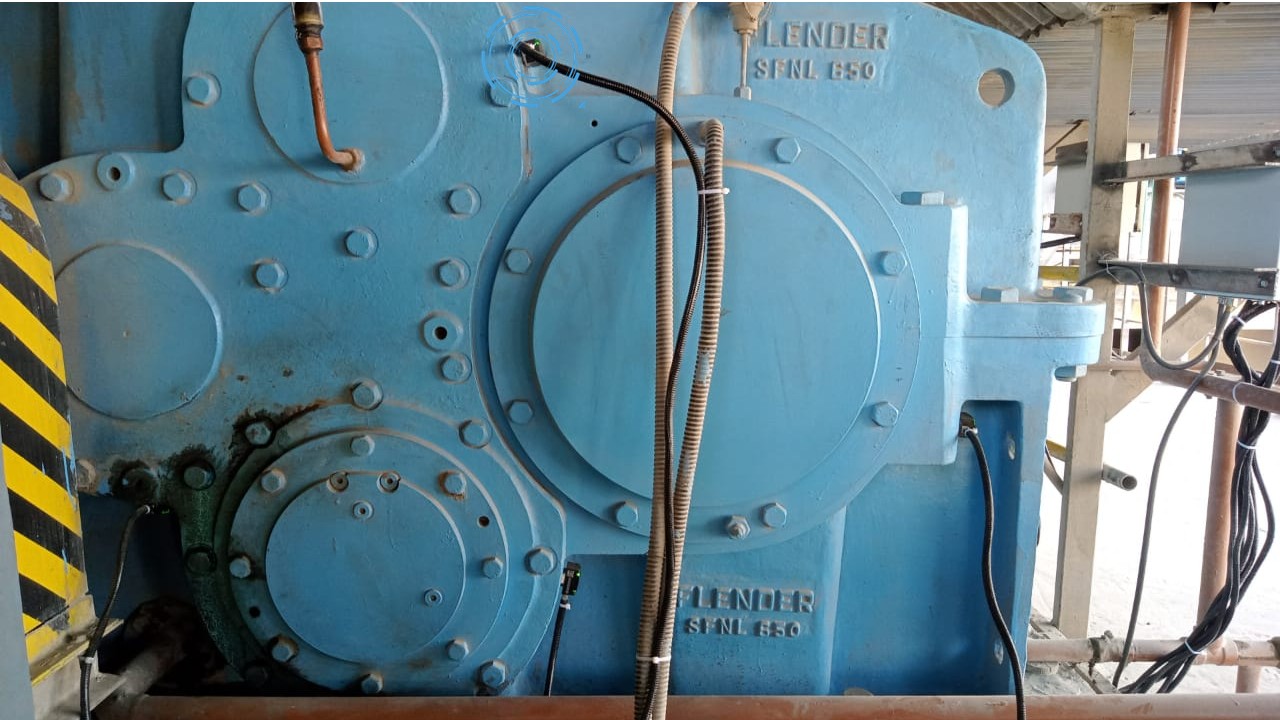

Critical Equipment

Main drive, tire, thrust roller and supporting roller are crucial.

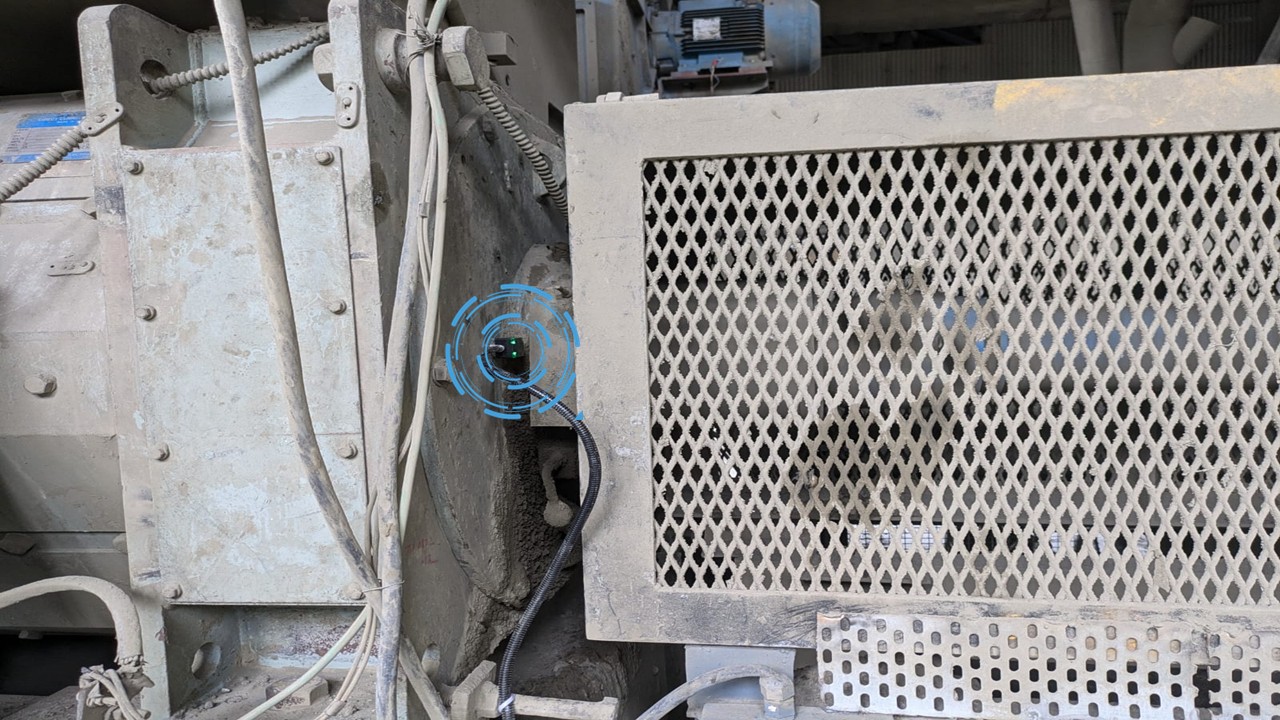

Critical Equipment

Pinion, main drive, motor and bearings are essential parts.

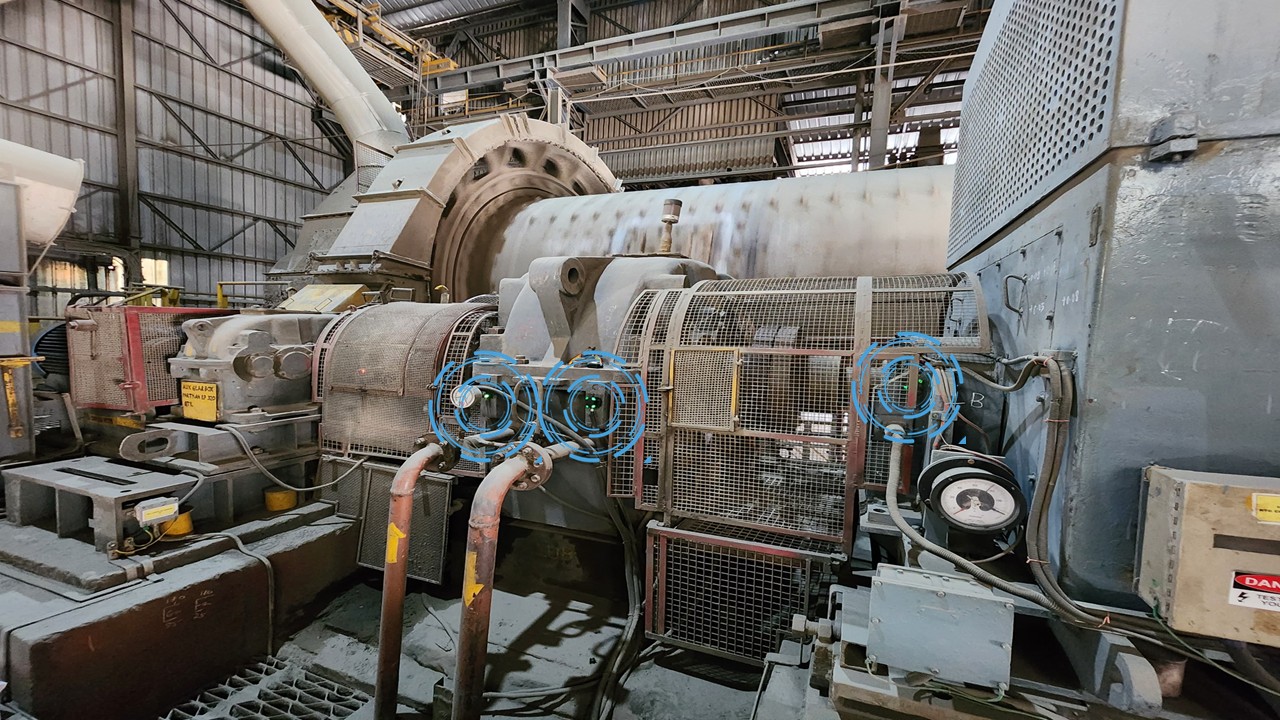

Critical Equipment

Kiln drives, roller press and special rotating equipment are included.

| KEY CAPABILITY |  |

COMPETITOR 1 | COMPETITOR 2 |

|---|---|---|---|

| CEMENT-SPECIFIC ASSET FOCUS | 80% deployments in VRMs, Kilns, Ball Mills, Drives; deep process understanding | Focus on mills and roller presses, less on complete kiln lines | General industrial monitoring, not cement-specialized |

| SENSOR & DATA TECHNOLOGY | Proprietary piezoelectric; built for harsh, high-temp, & dusty cement environments | Conventional vibration/temperature sensors; may not cover all cement environments | Standard wireless/IIoT; not certified for cement’s harsh conditions |

| FAULT DETECTION ACCURACY | 99.97%+ field-validated by cement users; <0.03% false negatives | No published accuracy or external validation for cement | Not published; relies on off-the-shelf ML models |

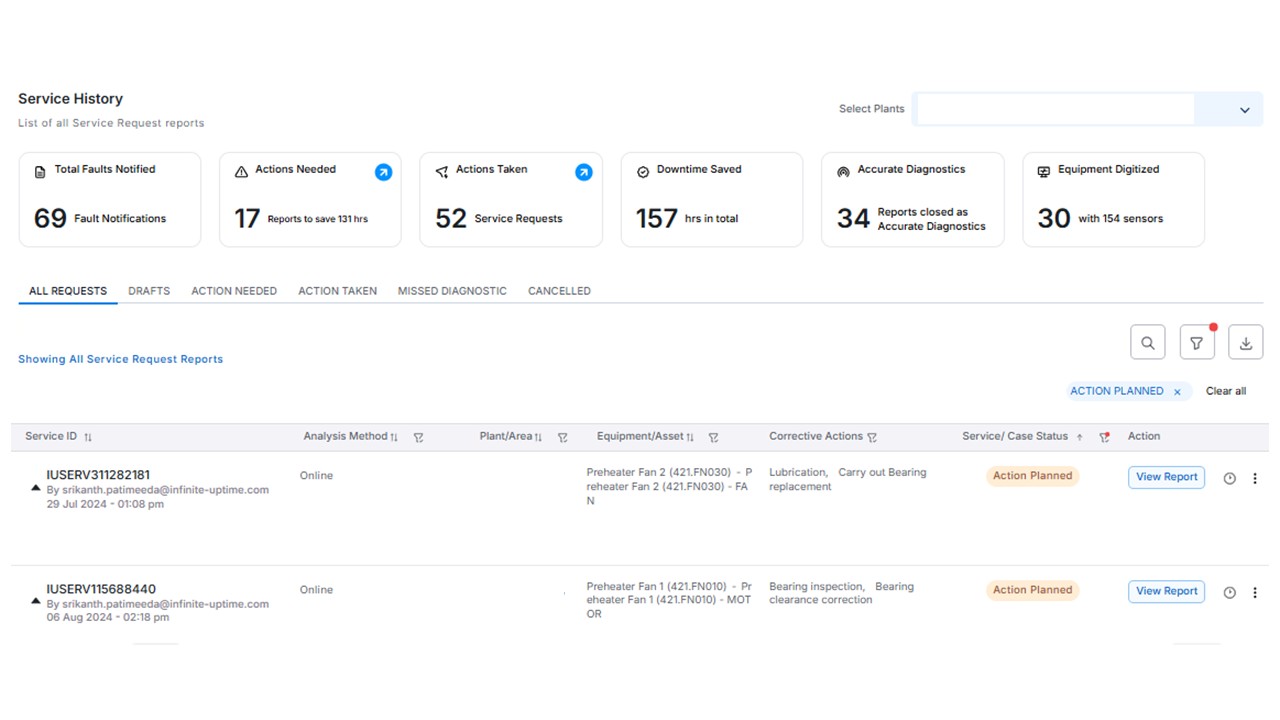

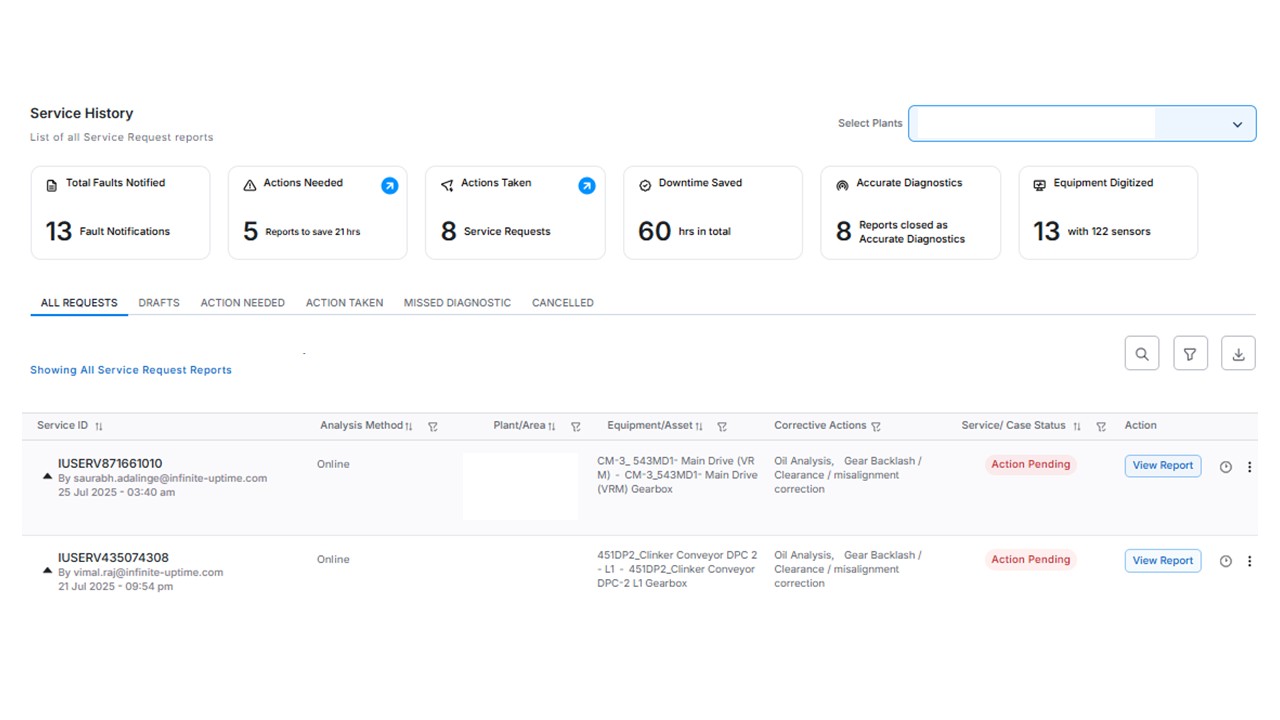

| OUTCOME DELIVERY | 100+ hrs production gain per plant/quarter ; full SLA-driven workflows for actionable repair | Historical/trend-based alerts; limited workflow integration | Data dashboard, few prescriptive insights or linked SLAs |

| COVERAGE OF CEMENT CRITICAL ASSETS | VRMs (all major OEMs), kiln drives, ball mills, roller presses, conveyors, fans — industry-leading breadth | Primarily presses/mills, limited kiln/rotary machine coverage | General plant machinery (motors, pumps, HVAC, etc.) |

| CYBERSECURITY & SCALABILITY | CB Insights top-rated; end-to-end encrypted, multi-plant, IT/OT-ready scalability — corporate IT standards | Standard security, no global cyber certifications published | Entry-level cloud/edge security; not industry certified |

| SUPPORT & PARTNERSHIP | Co-innovation/product roadmap for cement outcomes; on-site/remote expert teams; global user-proven adoption | European-centric, service/response time vary; less partnership emphasis | Few deployments in VRMs, Kilns, Ball Mills, Drives. |

| PROOF THROUGH OUTCOMES | 38,000+ hrs downtime saved; direct value for cement industry bottom line | Results published mostly in demos and pilots, not in validated cement deployments | No published cement industry outcomes |

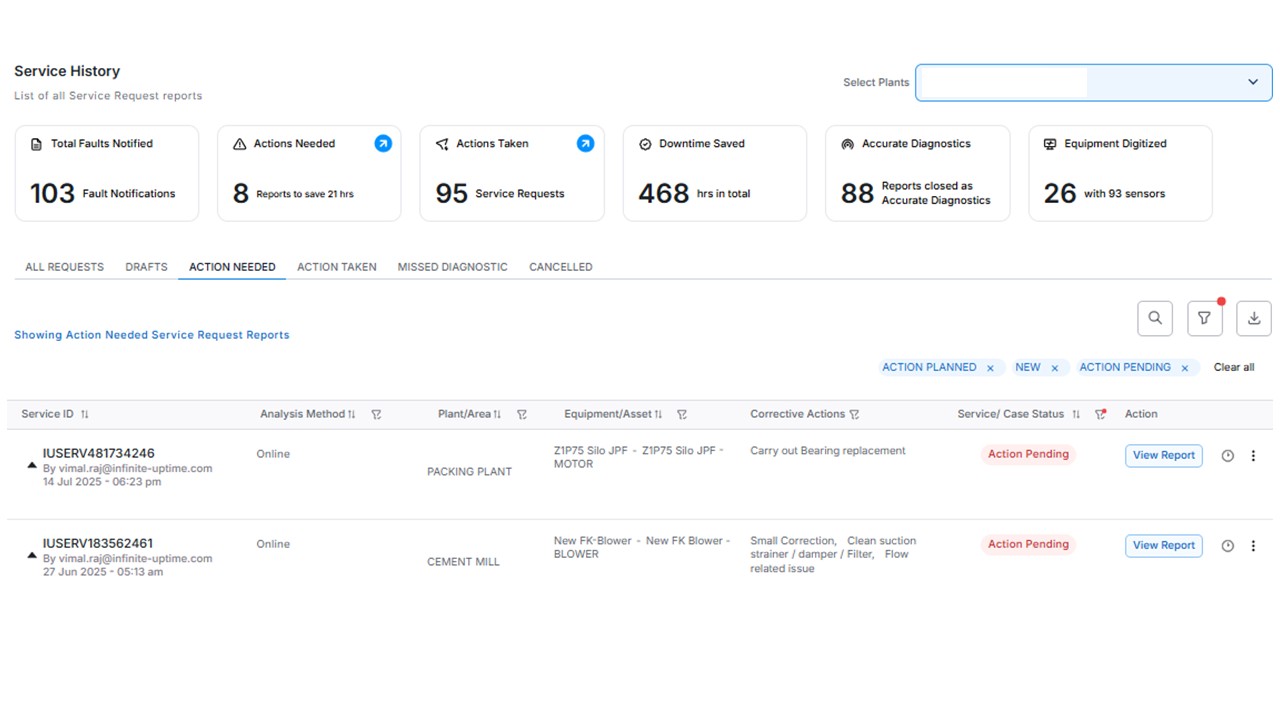

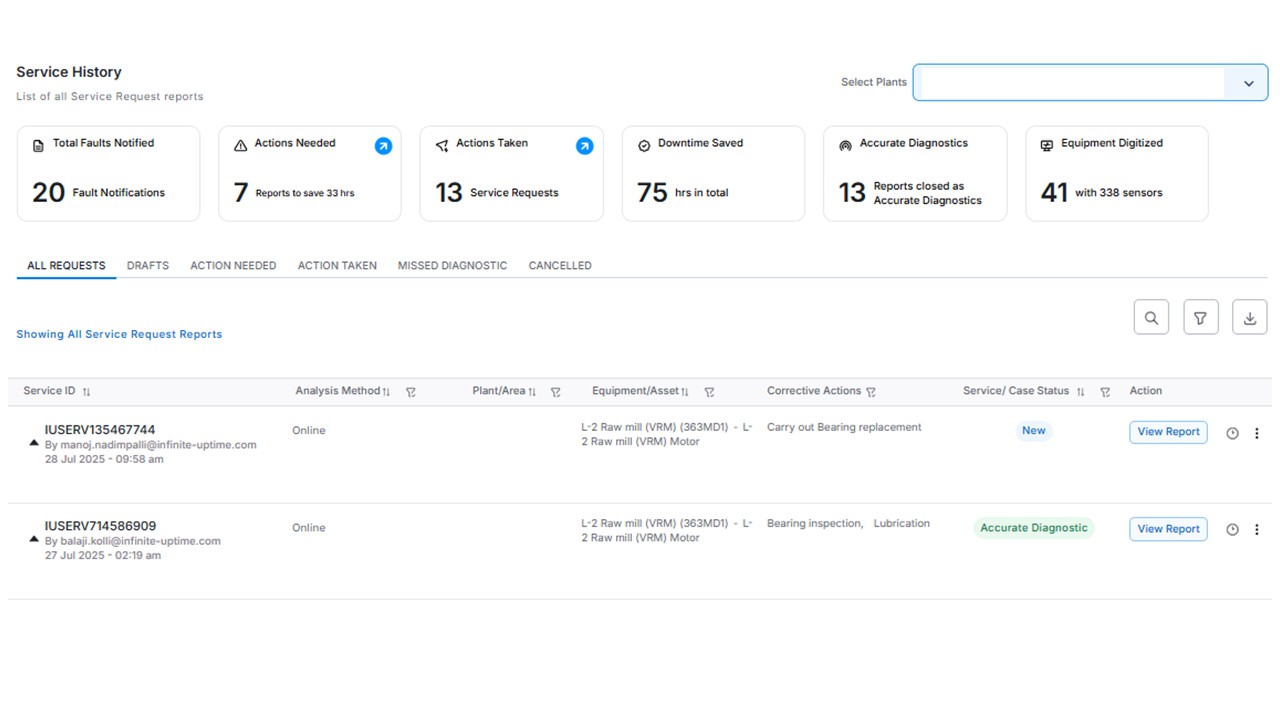

Prescriptive Maintenance

Prescriptive Maintenance Energy Efficiency

Energy Efficiency